PE (Polyethylene) vs FR (Fire-Retardant): What is the Difference and What Core Is Right for Your Next Project?

ALPOLIC® MCM are produced by continuously bonding two thin sheets of metal to either side of a thermoplastic core. The core produces a sheet that is lighter in weight and easier to fabricate, with superior flatness and durability compared to other cladding materials. ALPOLIC® produces two cores, referred to as PE and fr. The different cores provide the same variety of attractive finishes, structural performance benefits and come in the same dimensions. So how can you tell the difference?

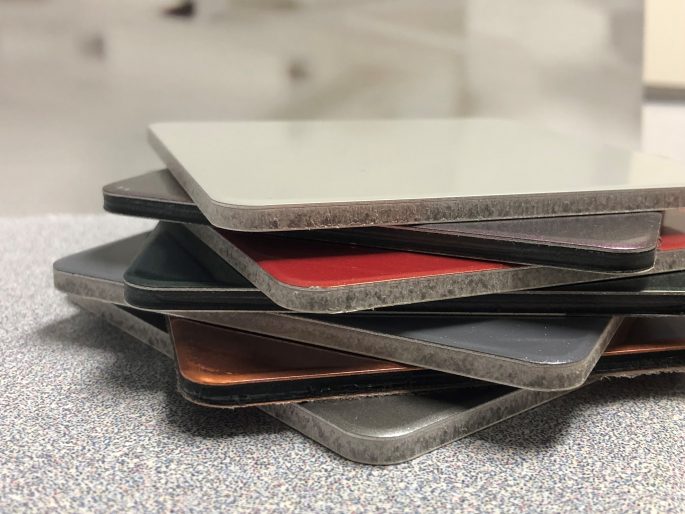

It is as simple as black and white (almost)

Visually, the core materials are easy to identify. ALPOLIC® PE, with a polyethylene core, is glossy black in color. ALPOLIC®/fr, with a mineral-filled, fire-retardant core, is a light grey color. Notably, the PE core is about two-thirds the weight of the fr. Both rated Class A under the ASTM E84 and the CAN/ULC-S102. The fr material has been used as a component in a variety of wall assemblies that have successfully passed the NFPA 285 and the CAN/ULC-S134. For this reason, ALPOLIC® recommends using fr core material when applied over 40 foot from grade.

Taking out the guesswork

Responsible building design requires that everyone, from the building owner to the architect to the contractor, take fire safety seriously. There are many layers of fire protection, such as prevention, suppression, and compartmentalization. Selecting the appropriate building materials are an important part of that conversation. ALPOLIC® is here to help make sure buildings clad in MCM are both beautiful and code compliant.

Wrisco is an ALPOLIC® Diamond Dealer Distributor.