Wrisco Industries is the number one company for metal fabrication and sheet metal fabrication process. We can save a customer money on a project from start to finish with our sheet metal fabrication process. Wrisco industries can customize a customers sheet metal based on the specifications of a customer’s drawings and provisions. The metal fabrication process is important for various industries that require sheet metal.

What Is The Sheet Metal Fabrication Process

- Fabrication Process

- Benefits

- Uses

Fabrication Process

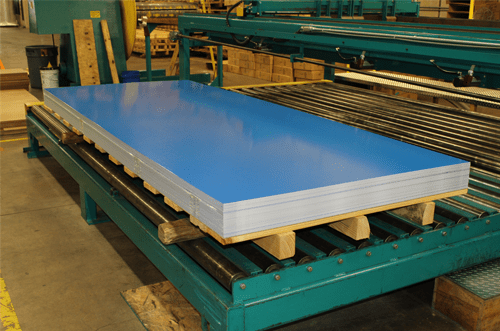

Sheet metal is a metal formed by an industrial process to thin, flat pieces of metal. This metal is one of the fundamental forms used in metalworking and can be formed and cut into a variety of shapes. Forming is the first step in the sheet metal fabrication process. Forming involves transforming the metal into the general structure of the product being developed. During this process forging, braking, stamping, and punching are all part of the forming process. Once the general shape is achieved the sheet metal cutting process will begin. This will allow the metal to form into a more desired size. Cutting the metal is done through various methods such as sawing, and touching. Torching is the next part of the process which involves oxy-fuel torches, plasma torches, and numerical control cutting.

Torching is a form of chopping metal. Oxy-fuel and plasma torches use gas and heat to chop sheet metal. Numerical control cutting relies on a computer program with cutting-edge technology to create a state of the art piece of metal. The last step in this process is finishing which gives the metal a smooth finished look. Bead blasting soda blasting, and sandblasting are all part of the finishing process. Wrisco industries can complete the finishing process with our state-of-the-art Turbobend Plus metal forming brake systems machine.

Benefits

Sheet metal fabrication allows for many benefits of the metal. Sheet metal is one of the most versatile and commonly used construction materials and is used in a variety of industries. Sheet metal has many benefits such as it is durable, weather resistant, and can be used for multiple purposes. This kind of metal has a low weight to thickness ratio which makes it simple to transport and work with. Sheet metal is also strong and durable which allows it to be resistant to ultraviolet rays, and moisture. This type of meal is widely used in the automotive, food service and healthcare industries and is a great metal for architects, engineers, and contractors to use in their work.

Uses

There are a variety of uses for sheet metal. Sheet metal is used for gutters on houses and buildings. Placing gutters or other water channels that are graded down to certain points of outlet will benefit from sheet metal. Once the rain falls, the water will drain from the roof properly which prevents the water from collecting around the building. Sheet metal is used to construct the wings and fuselages of an aircraft. This is an excellent material for an airplane as a result of it dealing with malleability and extreme temperatures.

Wrisco Industries is the best and most reliable company for metal fabrication and the sheet metal fabrication process. We have been in business since 1916 and have been providing exceptional services and products since we began. Call us today! At (800) 627-2646 To find out about our excellent metal products and sheet metal fabrication services.